Heat recovery

Recuperator — heat exchanger surface type for the use of exhaust gas heat in which heat transfer between the heat transfer fluids is carried out continuously through the wall separating them. Heat exchangers are distinguished by the relative motion of the heat transfer scheme — counter-current, co-current, etc., in construction — tubular, plate, ribbed, and others, on purpose — air heaters, gas, liquids, evaporators, condensers, etc.

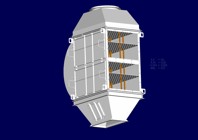

UC «AVK» produces direct-flow counterflow tubular heat exchangers.

Heat transfer in a recuperator is intensified by the special section of thin, rolled metal tubes, the beam of which is the basis of the unit. Wall vortex formed in each tube, on the one hand provides increased heat transfer and on the other — is destroyed before the air passage resistance increases.

Application exchanger makes better use of the heat of exhaust gases, which increases the efficiency of the installation. We manufacture heat exchangers for heat transfer fluid «fresh air» — a two-way and three-way design.

According to the " outgoing gases " - in the one-way design. Waste gases temperature 250-300 ° C are sent through the tubes of the tube bundle heat exchanger, and the fresh air passing through the annular space is heated to a temperature of 220-250 ° C.